E-Catalogue

About Us

As ÖZPOR brand; With years of experience, we produce original and high-quality productions on topics such as thermal insulation, sound insulation and fire insulation that come to mind first within the insulation sector.

With the assurance of our brand, which is present at every stage of the production process of insulation units that can be used in construction units that are in the process of new construction; At the same time, we continue to supply insulation layers to be used in future transformation projects.

Our company, which has the ability to assist in the application stages of primitive methods with the advantages of producing in the same sector for more than 30 years, with a service understanding that exists in very few regions of the world, is updating itself by closely following the developing technology with the advantage of this situation. has the opportunity.

You can also cooperate with ÖZPOR Stone Wool brand for the projects you design about insulation and you can have the best quality service understanding under the most advantageous conditions.

Information

Which product should be used in insulation projects? There is no clear answer to this question, which is questioned almost every time in insulation projects. However, as a result of the research on the most advantageous and efficient product among alternative products; The advantages of using rockwool products for every insulation project have a very high rate compared to alternative products.

Choosing more than one material for different insulation demands will be expensive in terms of production costs and will cause problems such as space narrowing.

Rock wool; due to the natural minerals in its structure and its form; It is a compact product that can be easily preferred for thermal insulation – sound insulation and fire insulation.

Having left behind its 32nd year in the sector with its industrialist identity, ÖZPOR is able to manufacture rockwool products whose quality and efficiency of use have increased considerably with the unique interventions it has brought to the world market in the production process.

We Get Our Strength From Nature

Almost all of the raw materials supplied in the production process are provided from nature. Rockwool, which is especially obtained from volcanic rocks and has a very low rate of accepting additional preservatives due to its structure, emerges as a result of the form change caused by the blending of volcanic lavas.

Thanks to the minerals and high heat it contains, the stone wool products included in the production process can provide serious gains in terms of both quality and cost to the companies it uses. The structure of rock wool productions used within the scope of ÖZPOR products, which are powered by nature, is up to 97% inorganic and therefore, it is not subject to any deformation during the usage process.

Operational Stages

The production and delivery process of the products obtained from rock wool continues around the world with different methods and in a more laborious way. ÖZPOR does not only increase its production quality for the world market. At the same time, it also considers the comfort of the brands it partners with. For this reason, it stands out as the first company in Turkey to implement the effortless delivery and carrying comfort practices that it integrates into the system, which are done by very few manufacturers in the world.

Within the scope of the operation stages of production; We offer you the “Stretch Hood” packaging method, which both prevents the loss of nearly 10% of the waste products lost by the receiving company during transportation and has the opportunity to be transported easily.

While delivering more compactly during the loading and unloading process; You will not pay extra costs for the system that offers palletized transportation.

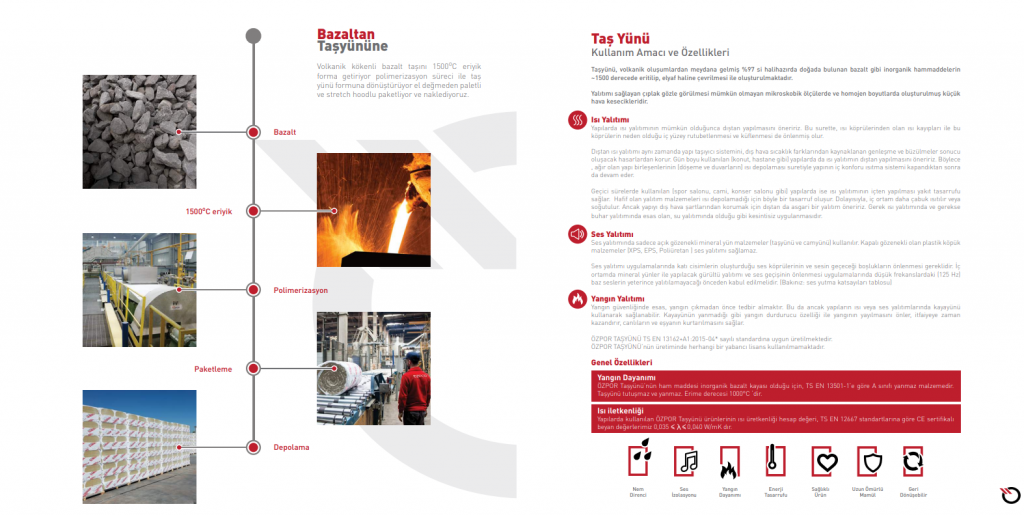

In the production phase of the products; There is a change from basalt to rockwool. In the production stages;

- Volcanic rocks obtained as basalt are primarily melted up to 1500 0C and form.

- The new form obtained goes through the “polymerization” stage under factory conditions in order to be converted to rock wool form.

- Finally, the products that meet with ÖZPOR’s original works go through the “packing” process, which has special and effortless conditions.

- The packaged products are shipped to the storage unit to be delivered to the business partners.

The products obtained are further classified according to demands and dimensions. To be preferred according to insulation demands; It is made ready in blocks as sound insulation – heat insulation and fire insulation materials.

ÖZPOR products, which have been continuing to serve the sector since 1985; At this stage, industrial boards are made ready for use as air conditioner boards or insulation boards.